We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What do I need to go round corners with LED Strip Lights?

There are several ways that strip lights can be installed around corners. This includes the use of solderless strip connectors, Hippo connectors, soldering or using bendable LED strip lights.

Cables

LED flex tape needs to be connected to a cable that can be bent to enable a connection around a corner. Unfortunately, this does create a gap between the two strips. However, it enables you to go around corners or objects without damaging the strip.

Simply cut your strip light to the required length on the marked cutting points. Then connect to the cables using the techniques described below.

Note: It is advised that when daisy chaining LED strips, do not connect more than 5 metres. Doing so may cause the strips to overheat and result in product failure.

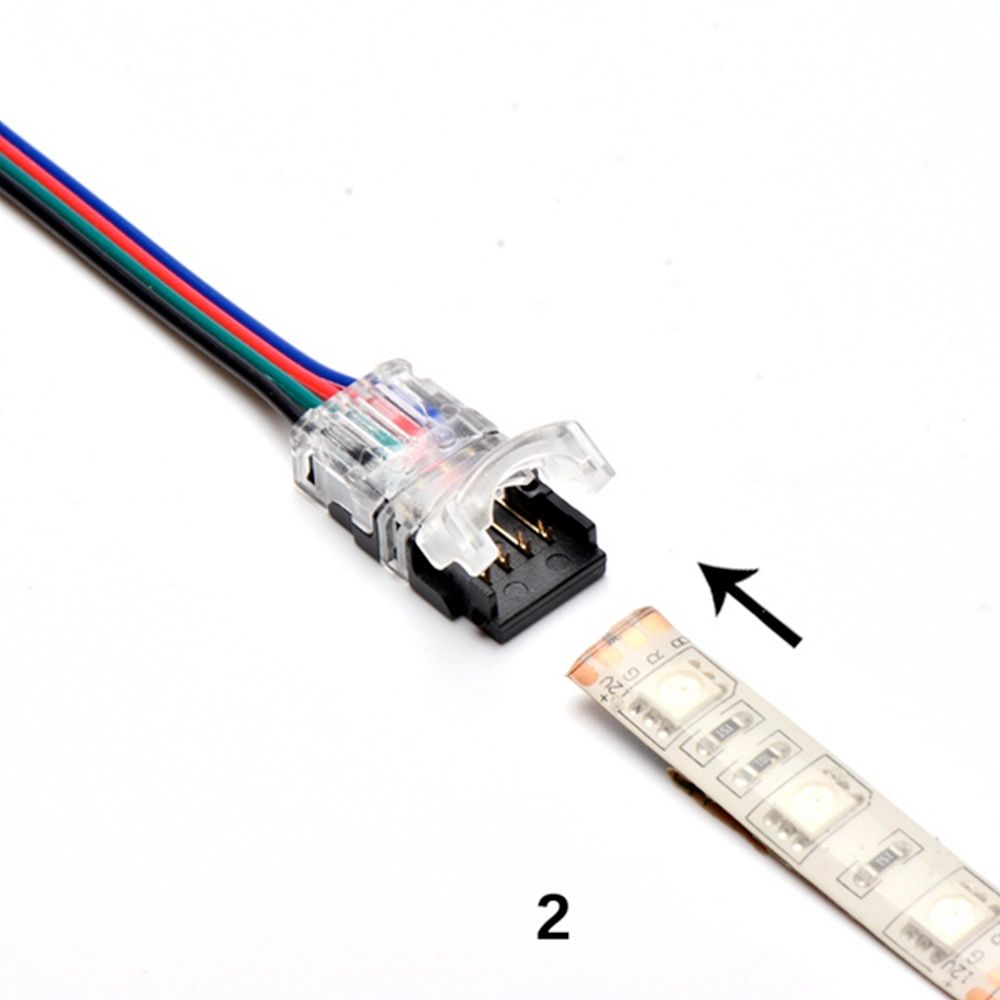

Solderless LED Strip Connectors

Solderless LED strip corner connectors make effortless work of creating a connection between strip lights around a 90 degree angle.

These high quality strip to strip connectors feature a simple clip fitting. Simply cut the LED strip on the marked cutting point. The copper or soldered tabs must be showing before joining the wires. Also ensure that the clear lacquer protecting the copper tabs is carefully scraped off to ensure a connection is made.

Simply open the connector and insert the LED tape into the slots on each side. Line up the copper tabs with the tabs on the solderless connector. Close the connector covers and firmly clip into place and ensure the locking tabs are latched.

The wire in-between the two strip connectors can then be easily bent and fitted to the corner. This enables a light connection around 90 degree angles.

We offer a wide range of solderless tape connectors from double, tri and quad connectors for any lighting project. We have connectors that come with 150mm pre-tinned tails that are colour coded for ease of connection.

Ensure that the connector is big enough to fit your LED strip into it. For example, our 10mm solderless double connector is suitable for 10mm LED strips.

The compact design and IP20 rating makes this a perfect solution for indoor installations. Ingress protection ratings indicate the protection against solid objects and water.

The first digit indicates the solid protection. In this case, the 2 means that it is protected against objects greater than 12.5mm, such as touching. The second digit is the water protection. In this case, the 0 stands for no protection against water.

Read our case study to find out more about IP ratings

It is an amazing alternative to soldering. However, it is not advised to use solderless connectors to connect LED strips for a long periods of time.

We recommend this technique for temporary lighting designs such as exhibition lighting or displays where quick and easy installation is required.

LED Hippo Connectors

Hippo connectors are also a quick and easy solution for connecting LED flexible strips around corners. This is a more reliable and stronger solution as it features prongs that pierce the circuit board. This creates a sturdy connection between the PCB and strip connector.

They reduce the time and need for technical experience with its easy installation. Easily place the strip and wires into the connector and then push the plastic covering down. Once the connectors are closed, it cannot be reopened de to its durable and firm connection.

Our strip to wire hippo connectors come in many varieties. Ensure you pick a suitable connectors with the correct amount of pins for your strip. For example, if you are using a single colour LED lighting, you should use the 2 pin hippo connector. You should also ensure that the width of the connector is big enough to fit the strip into.

We also offer IP20 for indoor uses and IP54 which can be used in damp environments such as kitchens or bathrooms.

These are a stronger alternative than solderless strip connectors, however are still not appropriate for long term installations. It is perfect where a quick and easy set up is required.

Soldering

The best solution to go around corner with LED strips is to solder the strips to the wire connectors. We offer a soldering kit that features a 30W soldering iron with precision soldering tips. It comes with everything you need to make a safe and secure connection.

This is the most reliable and permanent solution for creating connections. Ensure that the copper tabs are lined up properly to the wires to ensure a proper connection.

Soldering is a highly reliable under many conditions. It ensures that it is durable and will match the life span of your strip. However, this does require technical experience and greater investment of time and money.

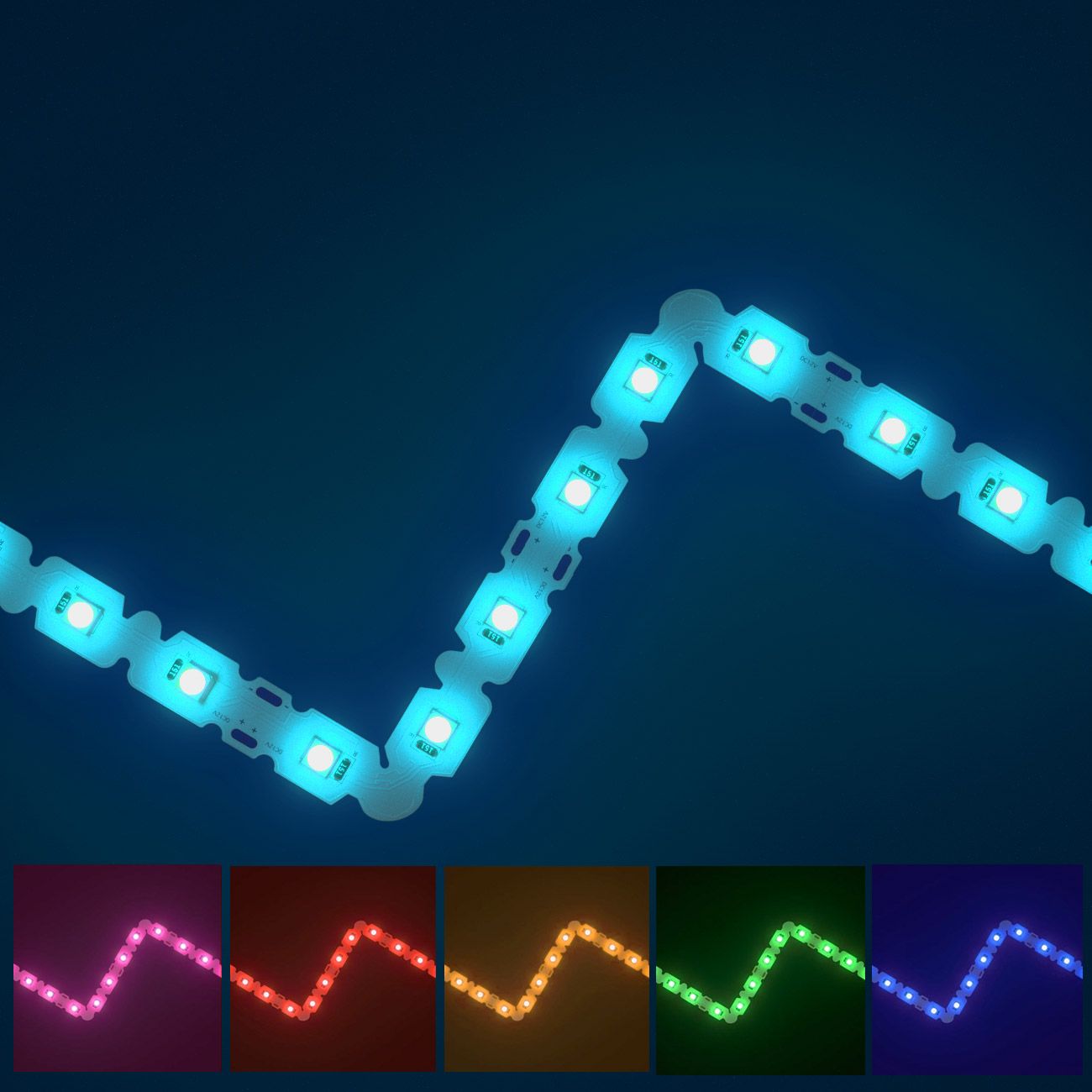

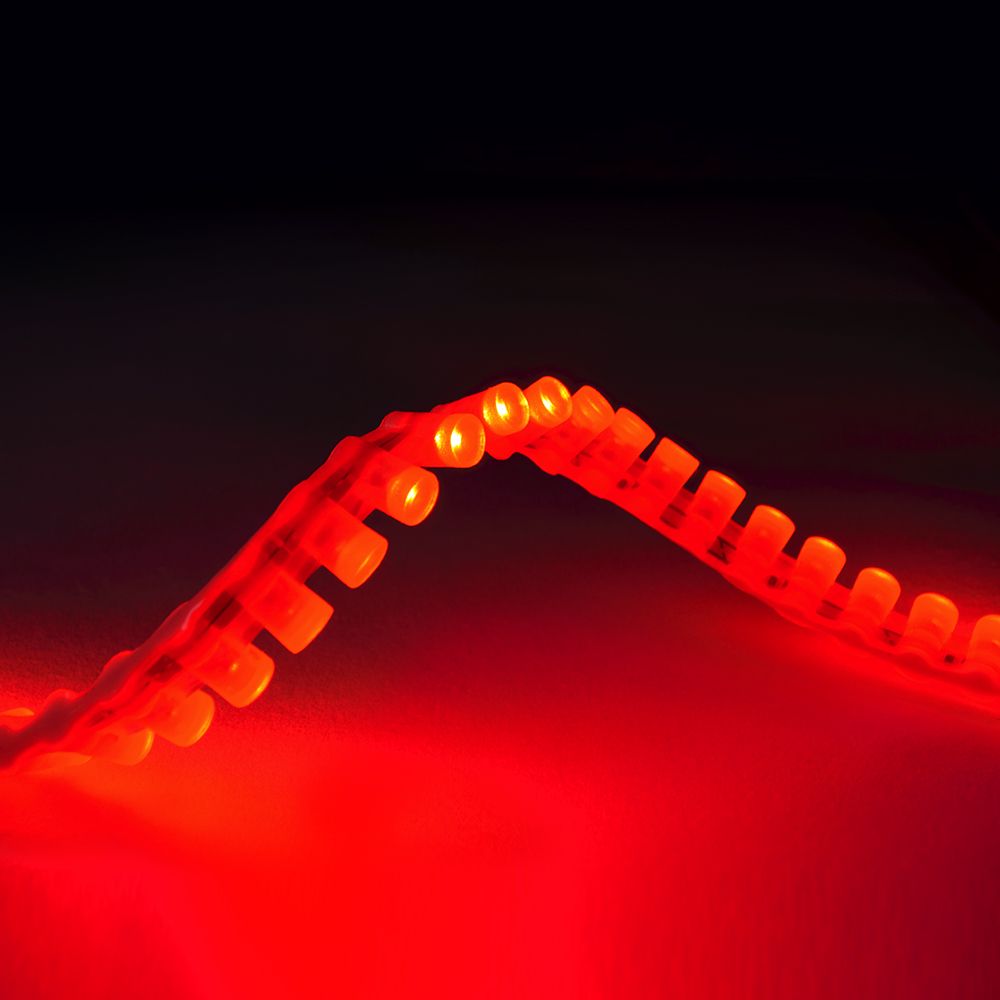

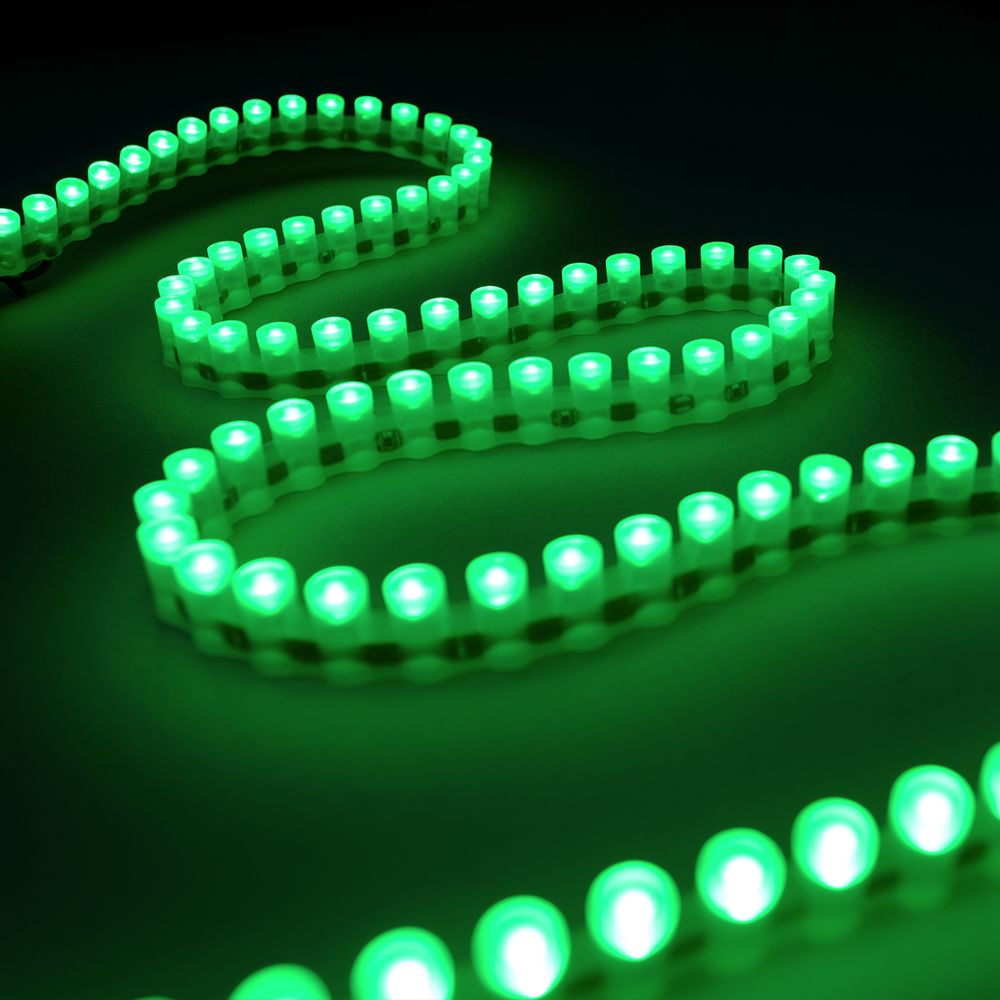

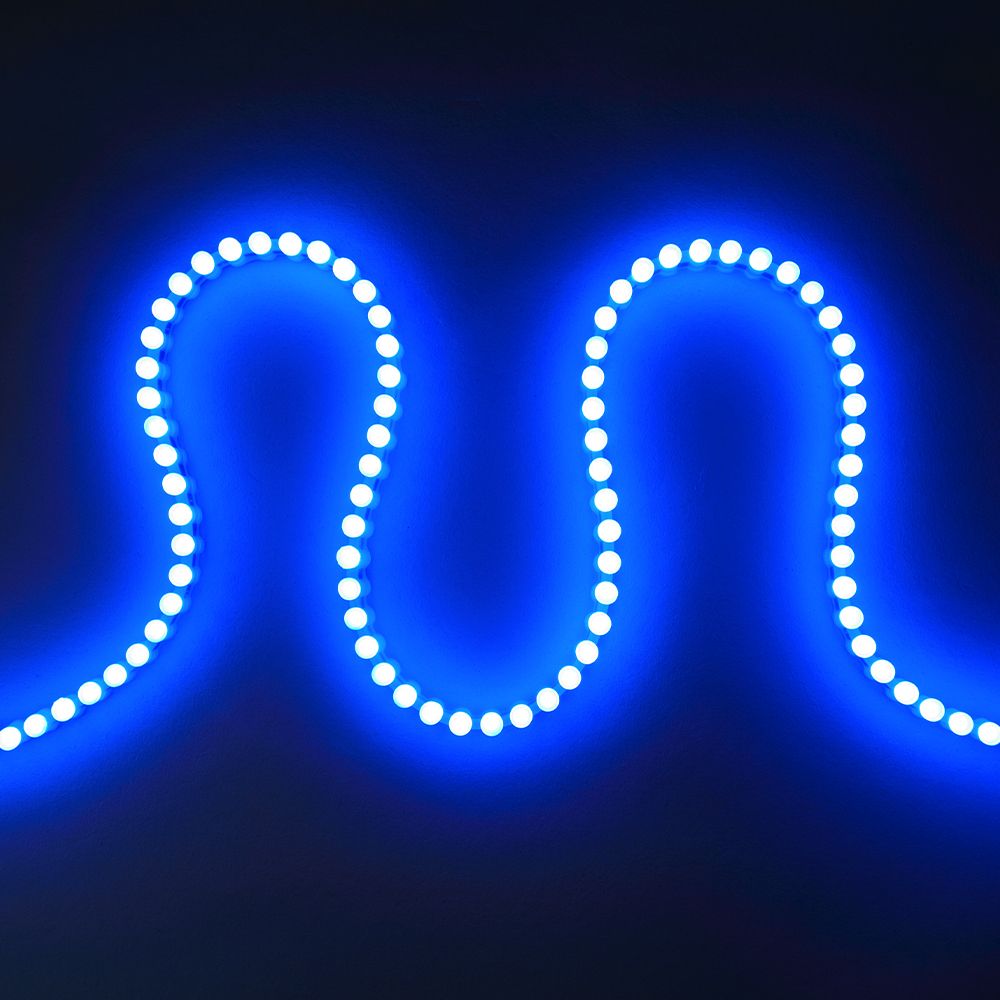

LED Bendable Strip Lights

The easiest solution is to chose a bendable LED strip such as the SideWinder or Flexi series.

These strip lights are designed to be extremally flexible. They are able to be adjusted up and down as well as left and right. This makes bending the strip around 90 degree corners effortless.

It requires no connections or wiring experience. It can also be instantly installed and usable in a matter of minutes. It also means that there isn't a gap so that a continuous line of light can be achieved.

Bendable LED strips come in a wide variety of options from single colour LED strips to RGB LED strips. We also offer a range of white strips in varying colour temperatures, from Cool White to Warm White. For whatever lighting effect or design you are looking for, we have the perfect bendable LED product to match.

Knowledgeable trained staff

Specialists in house to advise and specify the more advanced solutions.Speak to an LED expert today on 01260 540014